Playground equipment naturally wears down over time. A playground upgrade is in order when you notice signs of wear and tear.

Upgrading playground equipment takes careful planning, but each step is a chance to create something magical. From the first inspection to the final installation, you’re building a place where kids can climb, laugh, and shout with joy.

With the following safety considerations to keep in mind when upgrading playground equipment, you can replace worn-out parts and create a vibrant space for childhood memories.

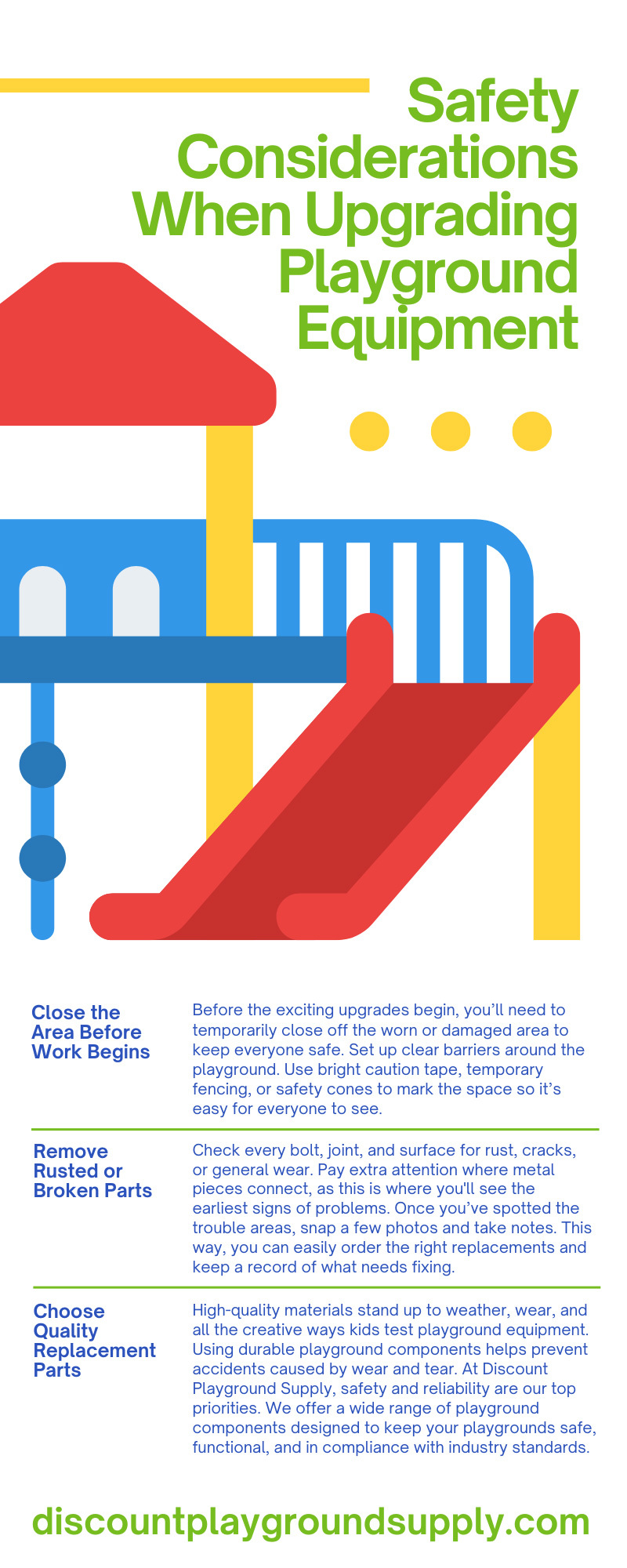

Close the Area Before Work Begins

Before the exciting upgrades begin, you’ll need to temporarily close off the worn or damagedarea to keep everyone safe. Set up clear barriers around the playground. Use bright caution tape, temporary fencing, or safety cones to mark the space so it’s easy for everyone to see.

Add some friendly signs to let parents and kids know the playground is getting a makeover, along with an estimated timeline for when the fun can start again. Communicating clearly not only helps families plan other activities but also builds excitement for the amazing new space that’s coming soon!

Remove Rusted or Broken Parts

Start your inspection by checking every bolt, joint, and surface for rust, cracks, or general wear. Pay extra attention where metal pieces connect, as this is where you'll see the earliest signs of problems.

Once you’ve spotted the trouble areas, snap a few photos and take notes. This way, you can easily order the right replacements and keep a record of what needs fixing. Instead of quick patches that might not hold up, fully remove those damaged parts to clear the way for stronger, safer replacements.

Take it slow when removing old pieces so you don’t accidentally damage the parts you’re keeping. Use the right tools for the job, and give the mounting spots a good clean once the old components are out. This extra step ensures those shiny new parts will fit perfectly and stay sturdy for years to come.

Choose Quality Replacement Parts

High-quality materials stand up to weather, wear, and all the creative ways kids test playground equipment. Using durable playground components helps prevent accidents caused by wear and tear.

At Discount Playground Supply, safety and reliability are our top priorities. We offer a wide range of playground components designed to keep your playgrounds safe, functional, and in compliance with industry standards. From swing brackets and slide anchors to replacement chains and hardware, every product performs under pressure.

With our extensive selection, you can tackle repairs confidently and ensure your playground continues to provide a safe, enjoyable space for the community.

Ensure Smooth Surfaces

Rough or splintered surfaces create injury risks that can turn playground fun into painful experiences. Replace worn or outdated wooden components with durable, splinter-free materials designed for long-lasting use. Choose protective finishes specifically crafted for playgrounds to ensure moisture resistance and added safety.

For metal components, upgrade to parts with smooth, rounded edges and rust-resistant coatings to enhance both safety and durability.

Include Guardrails on High Areas

[Image A]

Elevated features require additional safety considerations when upgrading playground equipment. Install guardrails on any platform, deck, or elevated walkway that rises more than 20 inches above the ground surface. These barriers must be tall enough to prevent children from accidentally tumbling over while remaining low enough to avoid creating climbing temptations.

Secure guardrails with robust mounting hardware that can withstand the forces children apply during active play. Test each connection point thoroughly after installation, applying pressure from multiple directions to verify that the barriers remain firmly attached. Remember that children often lean, push, and climb on guardrails in ways you might not expect.

Avoid Entrapment Hazards

Examine every gap, opening, and space in your playground equipment to identify potential entrapment risks. Head and neck entrapment poses the most serious danger, but fingers, arms, and legs can also become trapped in poorly designed openings.

Measure all openings carefully using proper gauges designed for playground safety assessments. Openings that measure between 3.5 and 9 inches create head entrapment risks. Similarly, spaces between 0.25 and 1 inch can trap fingers. Keep these guidelines in mind as you put your playground together.

Prevent Pinching With the Right Equipment

Moving parts create the most obvious pinch risks, but stationary components can also pose problems when children place fingers or clothing in gaps between surfaces. Examine every joint, hinge, and connection point for potential pinching hazards.

Pay special attention to spring-loaded equipment, rotating elements, and adjustable components. These features often create dynamic pinch points that change as children use the equipment. Test all moving parts thoroughly under various load conditions to identify potential problems before children begin using the upgraded equipment.

Follow Proper Installation Steps

[Image B]

Read manufacturer instructions completely before beginning any installation work, and gather all required tools and hardware before you start. Rushing through installation or skipping steps can create safety hazards that won't become apparent until equipment failure occurs.

Pay careful attention to torque specifications for all fasteners, as both over-tightening and under-tightening create safety risks. A bolt that's too loose can work free during use, potentially causing sudden equipment failure. Conversely, excessive torque can strip threads or crack components, leading to gradual deterioration and eventual failure.

Anchoring requires special attention since improperly secured equipment can tip over during use, creating serious injury risks. Follow anchoring specifications exactly, using the recommended hardware and installation techniques. Verify that anchors engage properly with the ground surface.

Put Periodic Inspections on the Schedule

Upgrading your equipment today doesn’t guarantee safety forever. Regular inspections are key to catching small issues before they turn into big problems, keeping kids safe and extending the life of your equipment. Set up a routine for visual checks, thorough reviews, and in-depth assessments to stay ahead of potential risks.

Make sure more than one staff member can handle inspections, so there’s always someone ready to step in. Equip them with the right tools, such as measuring devices and safety gauges, and use clear checklists to cover all the bases.

The sooner you act on inspection findings, the better. Putting off small fixes can lead to bigger, more costly problems down the line. Keep solid records of inspections and repairs to monitor performance and plan for future updates.