There are many arguments concerning the introduction of the playground and when equipment started to evolve. With the first swing set introduced in Ancient Greece, you’d think there was a full playground during that time. However, playgrounds didn’t manifest until sometime between 1859 in England and 1885 in Germany.

Since the introduction of the playground, equipment’s evolved over the centuries, starting with pipes and ending with metal. However, for the United States, it wasn’t until 1891 that the George Putnam School in Boston introduced the first playground. The playground equipment's evolution is still incomplete—there’s still much to learn about the potential future of engineering play gear.

Take a chance to learn about the complete transformation cycle to learn more about different materials used to give you a better understanding of where your gear comes from and how the manufacturing process looks today.

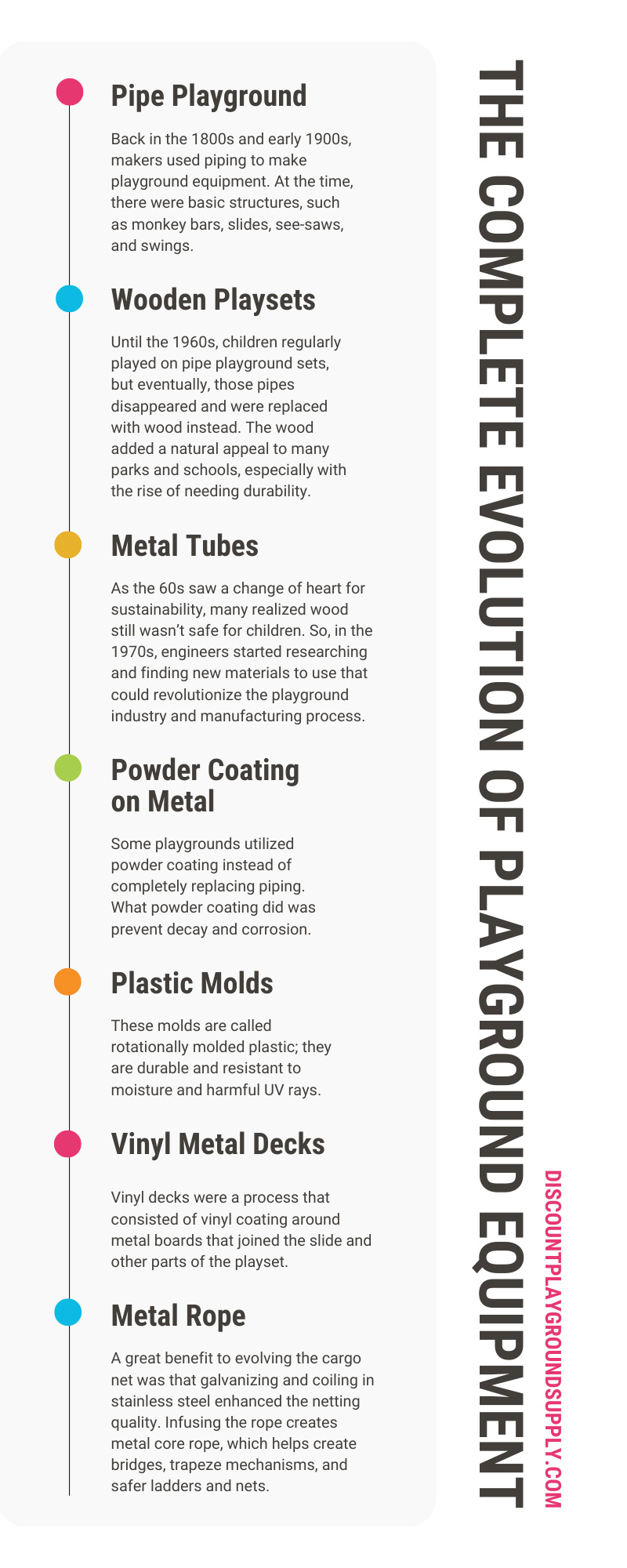

Pipe Playground

Back in the 1800s and early 1900s, makers used piping to make playground equipment. At the time, there were basic structures, such as monkey bars, slides, see-saws, and swings.

There weren’t any connections to the slides and monkey bars like we’ve seen between the 1990s and now. So, to go down the slide, children would form lines and wait their turn rather than go to other sides of the playground to slide.

Although piping was the preference for park administrators at the time, they didn’t live up to standards—the pipes corroded and had burrs on them that hurt children. After finding that tubes weren’t ideal, engineers got creative and resorted to wood, mainly because it was more natural.

Wooden Playsets

Until the 1960s, children regularly played on pipe playground sets, but eventually, those pipes disappeared and were replaced with wood instead. The wood added a natural appeal to many parks and schools, especially with the rise of needing durability.

While wood playsets gave new hope to developers, they weren’t the best. Yes, the wood did and still does add natural elements; however, the downside was the use of chemicals on treated lumber. The lumberyards would use arsenic to treat the wood to increase durability and fight decay. It may have been a helpful tactic, but it harmed children and the environment.

On the other hand, harmful chemicals weren’t the only thing harboring danger; termites and mold were among the other problems play equipment has encountered over the years. Other things like splinters and warping made equipment pieces unsafe to play on or be near.

Metal Tubes

As the 60s saw a change of heart for sustainability, many realized wood still wasn’t safe for children. So, in the 1970s, engineers started researching and finding new materials to use that could revolutionize the playground industry and manufacturing process.

With careful detailing, workers went in and tried metal tubes. Instead of large ones, they were thin. The thin design meant that it could fit any aesthetic while being easier to carry and care for. This tubing style also established itself in residential yards. Metal tubes, if applied with powder coating, are still used and enjoyed today. Even as playgrounds have evolved, so have the coating processes for commercial children’s play equipment.

Powder Coating on Metal

Some playgrounds utilized powder coating instead of completely replacing piping. What powder coating did was prevent decay and corrosion. The process first consists of applying multiple layers of galvanic and sealers. Then, it was sent through an electrostatic process and baked to dry the metal’s coating.

Today, the process is still used and is highly favorable for maintaining the durability of playground gear. One of the better things about the powder coating process is that it controls the surface's temperatures while being harmless to children.

Plastic Molds

Parks with toddler sections need equipment that fits a small child’s age range and abilities. Instead of using simple metal structures, manufacturers used plastic molds to create play pieces. What happens is that a portion of melted plastic goes inside a mold, which goes under extreme heat until thick on both sides. For both sides to bake thoroughly, the mold is rotated until fully thickened.

These molds are called rotationally molded plastic; they are durable and resistant to moisture and harmful UV rays. Additionally, if they get vandalized, any substance used is easy to rub off. Since the beginning of the 2010s, plastic has been the preferred choice over hot metal. Since metal heats fast, plastic weighs down the temperatures of burning suns by reflecting it off the material.

Vinyl Metal Decks

Manufacturers ventured into vinyl metal decks when bigger equipment pieces began to expand, such as having decks that connected everything. Vinyl decks were a process that consisted of vinyl coating around metal boards that joined the slide and other parts of the playset.

Vinyl coating formulas included PVCs, but once more research was conducted by groups of engineers, the PVCs were removed from the formulations to avoid harming the environment and children. Even without the PVCs, the vinyl decks have proven to resist corrosion and become a versatile, flexible material that improves the integrity of metal decks.

Metal Rope

For parks to create more natural sceneries, playground makers used metal rope, aside from wood structures. When first developed, makers had a formula that didn’t prevent moisture buildup, leading to ropes thinning and breaking. The metal rope workers used is called cargo netting.

A great benefit to evolving the cargo net was that galvanizing and coiling in stainless steel enhanced the netting quality. Infusing the rope creates metal core rope, which helps create bridges, trapeze mechanisms, and safer ladders and nets.

These fixes have enhanced playground equipment by taking it from the earliest evolution to the greater modern transformation. Your playground equipment shouldn’t be left to rot; it deserves a makeover and enhanced to improve the looks of the park and the overall community. Start by finding materials that enhance the park before rebuilding your structures.

Enhancing the park takes time, and you can get started today with Discount Playground Supply. Shop our fantastic online store to find all you need to complete the next evolutionary cycle of the playground. By focusing on one play area at a time, you can improve your park immensely.